Most darkrooms I have visited have one thing in common, regardless of whether they are in a prestigious university or a back room closet: Inadequate ventilation. Typically, I find a bathroom type exhaust fan mounted in the ceiling over the sink, which is mostly making a lot of noise and not moving very much air.

These exhaust fans are trying to lift aqueous-based photographic chemical vapors which are heavier than air. Since most are mounted in the ceiling, they are actually pulling the chemical vapors into the respiratory system of the student or printer working over the sink.

The kitchen range or restaurant vent hood type is also found in many darkrooms. This type of hood creates a lot of air turbulence around the edge of the opening. The primary reason this type of hood will work for kitchen and restaurant applications is that heat rises from the cooking surface. The rising heat actually pushes the fumes into the hood opening, where they are then captured inside the hood.

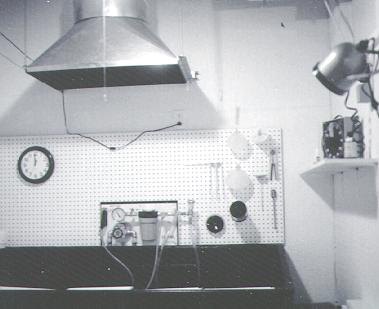

And, the higher this type of vent hood is above the sink the more turbulence it creates in the darkroom. And, it actually pulls more of the chemical vapors into the respiratory system of the student or printer working over the sink. A perfect example is shown below. This vent hood was totally ineffective in removing fix fumes from the darkroom and had to be replaced with two smaller hoods mounted at the back of the sink.

The Platinum printing process uses heavy metal salts and acids, which are toxic to the body and are difficult for the body to get rid of once they have entered. So, it is important for the printer to avoid exposure during chemistry mixing, paper coating, paper drying, developing and clearing their prints. To minimize exposure to the Platinum printer's respiratory system, I recommend that chemical vapor exhausting occur at the sink level, just above the tray level where the aqueous vapors are released. For proper exhausting I recommend a low profile vent hood that fits at the back of the sink and pulls the vapors away from the front of the sink, where the photographer is standing. An example of this type of hood is shown in the photograph below.

The air velocity at the low profile rear exhaust vent hood must be designed so there is sufficient air flow to capture the chemical vapors at the front of the sink and exhaust them from the room.

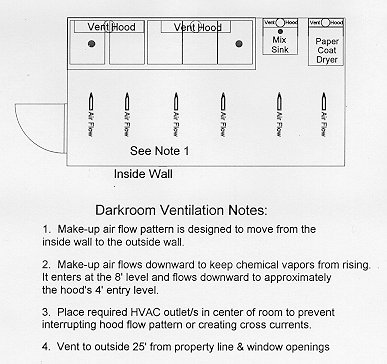

I have included a darkroom design below that incorporates this type of ventilation system.

Notice in the Elevation View

the room make-up air, as indicated by the arrows, travels from the opposite

side of the room, and it is always pushing the chemical vapors down towards

the back of the sink, where the vent hoods pick up the vapors and exhaust

them out of the building.

Darkroom Layout

|

|

By pushing the chemical vapors in the sink down and back towards the rear of the sink, it keeps them out of the respiratory system of the person working over the sink. So, its important to place the light tight louvers above the head of the printer, and not what is typically found in most darkroom as shown below. Note 2 indicates that make-up air should enter the room at the eight (8) foot level.

In addition to a complete parts list for this type of ventilation system for a typical Platinum darkroom (I know, no such animal exists), resources for parts and design information have been listed. Galvanized sheet metal duct and fittings can be purchased locally or through mail order from the listed sources. U.S. Plastics has a full line PVC duct available for a more expensive option to galvanized sheet metal. Grainger is a national industrial supplier that sells to businesses and can usually be found in the business pages of the telephone directory.

Low Profile Rear Exhaust Vent System Parts List

| Qty | Description | Part Number | Source |

| 2 | 48 X 24 Rear Exhaust Vent Hoods | 48X24VH

35543 6B-11556 |

Edwards Engr Products

U.S. Plastics Corp Lab Safety Supply |

| 2 | 24 X 12 Rear Exhaust Vent Hood | 24X12VH

35539 6B-11554 |

Edwards Engr Products

U.S. Plastics Corp Lab Safety Supply |

| 2 | 8" diameter 90 degree Elbow | Home Centers, Bldg Supply

Air Handling Systems Oneida Air Systems |

|

| 2 | 8x8x8 Wye 45 degree 26 Ga | Home Centers, Bldg Supply

Air Handling Systems Oneida Air Systems |

|

| 2 | 8x8x6 Wye 45 degree 26 Ga | Home Centers, Bldg Supply

Air Handling Systems Oneida Air Systems |

|

| 15' | 8" diameter 26 Ga Galvanized Duct | Home Centers, Bldg Supply

Air Handling Systems Oneida Air Systems |

|

| 10' | 6" diameter 26 Ga Galvanized Duct | Home Centers, Bldg Supply

Air Handling Systems Oneida Air Systems |

|

| 5' | 10" diameter 26 Ga Galvanized Duct | Home Centers, Bldg Supply

Air Handling Systems Oneida Air Systems |

|

| 8' | 8" diameter Flexible Duct | 36059

08CVD FLEX8 |

Home Centers, Bldg Supply

US Plastics Air Handling Systems Oneida Air Systems |

| 8' | 6" diameter Flexible Duct | 36057

06CVD FLEX6 |

Home Centers, Bldg Supply

US Plastics Air Handling Systems Oneida Air Systems |

| 2 | 8" diameter blast gate or butterfly damper | Home Centers, Bldg Supply

Air Handling Systems Oneida Air Systems |

|

| 1 | 6" diameter blast gate or butterfly damper | Home Centers, Bldg Supply

Air Handling Systems Oneida Air Systems |

|

| 1 | 8" Take-Off Flange | Home Centers, Bldg Supply

Air Handling Systems Oneida Air Systems |

|

| 1 | 1000 CFM PSC Blower @0.8" SP 115 VAC | 4C831 | Grainger |

| 1set | Blower Housing Supports | 2C335 | Grainger |

| 2 | Silicone RTV Sealant Clear or Gray | Home Centers, Bldg Supply | |

| 200 | #8-3/4" Self Tapping Sheet Metal Screws | Home Centers, Bldg Supply | |

| 7 | 14x6 Return Air Grille | Home Centers, Bldg Supply | |

| 7 | 14x6 Adjustable Face Register (Air) | Home Centers, Bldg Supply |

Basement Dark Room Design - Even a darkroom build in a basement with an 8 foot by 8 foot area (from the layout below) can be effectively ventilated to protect the photographer.

The ventilation system was simple and the installation was quite easy as shown below.

The blower had to be put inside the darkroom and not outside the wall as shown in the layout. But, if you have the luxury of having an attic or false ceiling above your darkroom, it would be easy to put the duct work above the ceiling and out of sight to reduce the noise from the ventilation system. So, keep this in mind when planning your system.

Custom Darkroom and Ventilation Design Question?

If you have any ventilation problems or design questions, feel free to contact me at 512-529-0538 or by e-mail: at eepjon@aol.com

Jon Edwards

Darkroom Ventilation Resources

Galvanized sheet metal duct and fittings available locally or through mail order sources.

|

Air Handling Systems

800-367-3828 http://www.airhand.com/ Oneida Air Systems

|

| Resources: | Phone Numbers: |

| Edwards Engineered Products | 512-267-4274 |

| U.S. Plastics Corp. | 800-537-9724 |

| Air Handling Systems | 800-367-3828 |

| Oneida Air Systems | 800-732-4065 |

Overexposure, Health Hazards in Photography, Shaw and Rossol, Allworth Press, New York.

Industrial Ventilation, American Conference of Governmental Industrial Hygienists, 6500 Glenway,Cincinnati, Ohio 45211.

|

|

UV Light Sources |

|

|

|

|

|